This program sponsored by TelecomCareers.net

General Electric is not typically known for being a telecom powerhouse, but as the company continues to diversify, its energy branch, GE Critical Power, is finding new ways to power telecommunications equipment.

In this edition of “Digs,” RCRtv takes you inside GE Critical Power’s labs in Plano, Texas to see how the company designs and tests critical power components for telecom and data centers.

“All equipment including central offices need power and that’s what we do…on the component side, we design and manufacture DC to DC switch power supplies, AC to DC switch power supplies. We also provide DC systems and AC systems,” GE Critical Power’s Plano Technology COE Leader, George Alameel said of the company’s core offerings.

Alameel takes us inside GE’s point of load lab where the company manufactures small point of load processors for everything from 3 amps to 170 amps.

“If you have a processor or memory chip depending on the power level that you need, these point of loads will do perfect, so a customer will place the point of load in front of their processor, and whether its one volt or five volt, the point of load will deliver the current needed to power that component,” he said.

In addition to the point of load lab, Alameel showed us the mechanical lab to see a wind tunnel environmental stress test designed to identify a safe temperature a product can deliver at a certain power level.

“Our mechanical engineers need to show customers data at different ambient temperatures,” Alameel said of the purpose for the tests. “Some customers operate at 70 degrees [Celsius], some operate at 50 degrees [Celsius], so what our guys do using a wind tunnel testing is to provide…derating curves for a customer that tell them this is how much power you can get at this ambient temperature if you have this airflow and we have 200 feet per minute, 400 and 800 feet per minute for each test.

We also got to look inside the magnetic lab where engineers design and analyze magnetic components for DC to DC switch mode power supplies and the EMI chamber where the company tests electromagnetic interference.

Alameel says GE Critical Power employs four different types of engineers: Mechanical, electrical designers, magnetic designers and software engineers who design controllers for the company.

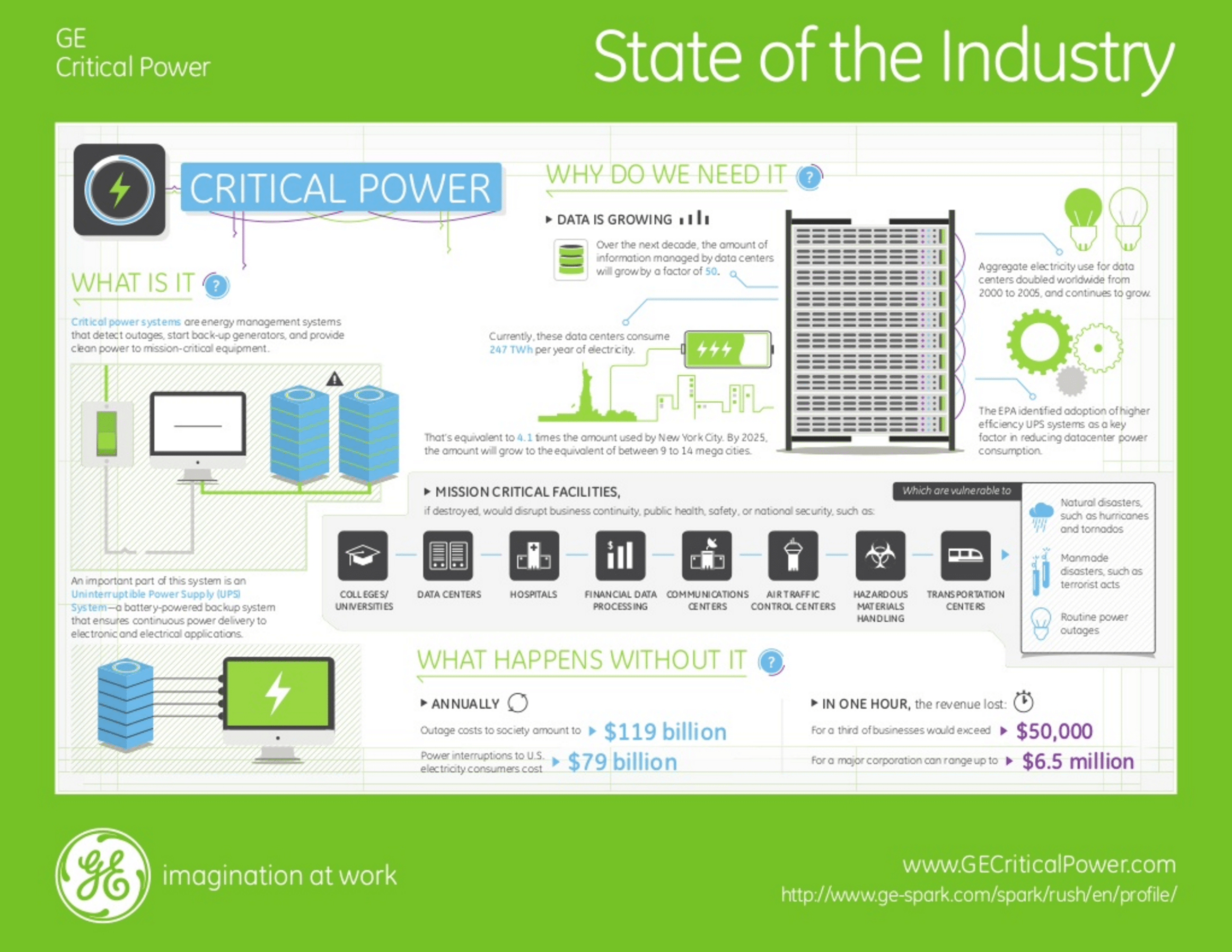

This graphic helps explains the importance of critical power sources.