One would be forgiven for thinking the Industry 4.0 game is all about shiny new private 5G networks. Certainly, the telecoms hype machine, and much of the telecoms trade press, says so. But industrial intelligence did not start with 5G, clearly (and has not gone very far with it, as yet). Instead, it has developed quite well with Wi-Fi and fibre technologies, plus plenty of others. LoRaWAN is one of these others.

Like most of them, it has been enabling private networks for years already – even as the ‘private networks’ buzz has tended to obsess about cellular (more meaningfully with cellular-LTE, more hopefully with cellular-5G). The point is only that mention of LoRaWAN, a low-power wide-area (LPWA) technology which has done the IoT donkey-work for years, in a press notice from a big automaker about Industry 4.0 optimisation should not be a surprise.

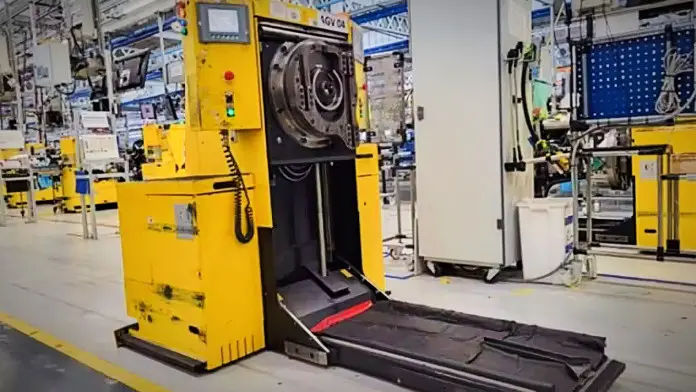

So, to the news: Volvo Group, the Swedish truck manufacturer, has deployed a private LoRaWAN network at a facility in Lyon, in France, in order to manage its autonomous guided vehicles (AGVs), ferrying parts around the manufacturing floor. Say what? To be clear; no, Volvo is not using LoRaWAN to orchestrate a fleet of wheeled logistics robots, as per the classic private 5G use case. Instead, it is running LoRaWAN for predictive maintenance.

Which, of course, is the classic use case for industrial IoT – to run live diagnostics from strategically-placed IoT sensors to gauge the health of industrial machines, whether static or mobile. The news is a reminder that classic IoT – running on humble LPWA networks of various sorts, developed over many difficult years – still works, works well, and justifies a declamatory kind of press missive. “New exciting opportunities,” it stated.

Specifically, Volvo Group uses AGVs to transport heavy engines – for trucks, boats, and industrial power systems – about the Lyon workshop. They run on 24 volt batteries, which fail when the voltage goes under 22 volts, and halt the AGV fleet and block the production chain. The firm said the power issues in its AGV fleet caused production rates to slip by around two engines per week. A LoRaWAN-based solution has solved this, it said.

The statement reads: “The team initially looked at Wi-Fi, but the Wi-Fi 2.4GHz band was already used for critical processes… [So it] looked at LoRaWAN… [– which] is ideally suited to the manufacturing process as it provides long-range capability, good resistance to interferences, and a secured and flexible network architecture. The team installed… LoRaWAN sensor(s) on every AGV to receive periodic voltage data of battery levels or failures.

“The maintenance team receives regular notifications, providing more time to move the AVGs to the charge point without blocking the production line. They can also organize interventions in cases of battery failure. The complete system for predictive maintenance now includes a LoRaWaN sensor installed on every AVG, a private LoRaWAN network, a maintenance platform [and] mobile application, and screens to display the real-time status of any AVG.”

Volvi Group has gone with hardware from Multi-Tech and a cloud platform from PTC (Thingworx). It said new sensors have been added to the network for additional purposes, including temperature and humidity sensors to improve the rendering quality in paint jobs, and pressure sensors for monitoring filter clogging.

Julien Bertolini, principal IoT solution architect in Volvo Group’s digital and IT division, said: “Implementing a radio infrastructure in our factory was a challenge, and we wanted to have a LoRaWAN network connected directly to our Ethernet network to avoid any cloud dependence. We selected a Multi-Tech LoRa gateway, with some edge computing capabilities and robust cybersecurity features to successfully qualify it through a complete IT audit.”